In this webinar on solar carports, we go beyond the fundamentals of configurations and optimizations to discuss key engineering decisions, installation process and services, and marketing and brand opportunities that reduce the cost and increase the value of the investment.

- About Polar Racking

- Are there standard solar carport designs?

- What services does Polar Racking offer?

- What are typical lead times for solar carports?

- Solar Carport Process: Getting Started with a Quote

- Solar Carport Configurations

- Foundation Design for Solar Carports

- Design Considerations of Solar Carports

- Geotechnical Engineering Services

- Installation Services and Training

- Frequently Asked Questions

- Question Period

Vishal Lala: Hey, good afternoon, everyone. Welcome to Polar Racking’s Buyer’s Guide to Commercial Solar Carports. My name is Vishal Lala. I’m the Managing Director of Polar Racking. And, thank you very much for taking the time today, this hour, to spend with us to learn more about solar carports and our offerings.

Excited to present the information to you and as always answer your questions. We do have the chat feature set up here. So as you think of the questions, please don’t wait. Just add them into that chats room. We’ll take the time at the end of the conversation or end of the presentation to answer all the questions to the best of our ability. We will get back to you with anything we don’t have at our fingertips right now.

Presenting with me today will be Jonathan Mizrachi. He’s our Sales Director in the U.S., based in Long Island, and the carports expert here today. We’re quoting and selling a lot of them, especially in the Northeast right now. So with that said, I’ll talk about Polar Racking and then hand it over to Jonathan to tell you a little bit more about our solar carport offering.

About Polar Racking

Polar Racking was founded in 2009. We currently have offices in Ontario, Canada, and New York, and Ohio. We started as a rooftop racking manufacturer way back, 12 years ago. But since then, we do flat roof, flush-mount rooftop, ground mount, fixed ground mount, and carport racking. We also supply a variety of foundation solutions, so we make our own ground screws and helical piles, and we’re able to supply driven piles as well.

With our ground mount systems, we also supply ballasted systems – pour-in-place, pre-cast ballast, and geo-ballasts solutions as well. Here’s a quick look at our product line-up. PRG is our flat rooftop product. Again, you have all the foundation options.

We have our flush mount product, what we call PRR. PRU-D is our distribution ground mounts. So it’s a pre-engineered ground mount system available through distributors for small ground mounts, so anything less than 500 kilowatts. PRU is our utility-scale ground mount system, which is custom-designed for your site location.

And that is anywhere from 500 kilowatts to 500 megawatts essentially or greater. And then PRP is our solar carport solution, which we’re here to talk about today. So with that, I’ll hand it over to Jon to take it forward next.

Jonathan Mizrachi: Thank you Vishal, and welcome everyone. Excited to be here today. Look forward to the presentation, talking about carports with Polar Racking. We’ve been busy this last year and a half with our carports. It’s a really exciting product. I know a lot of developers, installers, and the like, and we receive constant phone calls, which is a good thing.

And it seems like there’s a lot of traction out there in multiple markets for carports. So some of the biggest things that we see with, development of carports is that it allows you to use space that otherwise was not used. So a lot of times, we have clients who may have installed the rooftop system, let’s say on a building. But they have some ample parking lot space. Whether they’re going behind the meter or in front of the meter with maybe a community solar program or something like that, it just allows you to offer another product line to an existing customer. I think that is the point that I’m trying to get at.

Are there standard solar carport designs?

We have a very customizable approach and solution. I get a lot of questions where folks ask me, “Hey Jonathan, what’s the standard solution that you use for a parking lot like this?” Well, the real answer is there is no sort of boilerplate or template solution. Every parking lot is different. Measurements will be different. The angle of the parking spots may be different. Application, soil conditions, just variable winds and snow loads, so everything is custom when it comes down to the carport design and how do we want to place footings and canopies, that sort of thing.

What services does Polar Racking offer?

At Polar Racking, we do provide in-house design engineering, project management, and installation services. You could pretty much pick and choose as much or as little of these services as you need. The first two, the in-house design and engineering, give you a stamped, racking plan set.

But as far as project management and installation services, we get customers that want us to manage the project and install the foundation and the rack. We have others that are well equipped to do so and decide that they want to do it. And we just supply materials at that point.

What are typical lead times for solar carports?

Lead time is a big one that comes up as well. Lead times right now with a constrained supply chain really have extended out. We’ve been able to keep ahead of that – secure our steel and manufacturing through a network of plants that we use. So we’ve been able to keep our manufacturing timeline down to a 10- to 12-week turnaround, including engineering and so forth.

That’s good considering the market conditions today with all the turmoil. It’s not only about the pricing alone, but it’s getting the steel itself; the raw materials are really important.

So just some things to keep an eye out for there.

Solar Carport Process: Getting Started with a Quote

Jonathan: All right. So what we first wanted to show everyone today is the process. How do you submit a project that you’re looking at, or what would you like to begin with? We have some cool features here on our website. It’s called Start Your Order. You simply will click on that button.

There are two locations. There’s one in the upper right-hand corner that you see there. And then, of course, one right in the center of the page, big blue button, click Start Your Order. Once you click that, you have to select from one of the product lines that we offer.

Essentially you can select from ground mount, either rooftop, whether it’s ballasted with the PRG system or rail system with PRR. Of course, today we’re talking about carports and lastly solar foundations, we do offer, some geotechnical services, and supplying foundation to a lot of other vendors and large developers out there.

So right here is where you input all the information in the form, right? We want to know who you are, what the project is. Where’s the project located? What’s the size of the project? How many modules, what type of modules? Right? So this is really important stuff that we’re going to go over today.

Further into the presentation, we will cover what are we looking for such as the panels that determine the space of the canopy, the size of the system, and the size of steel that’s needed. We also would like to see the module datasheet, installation manual. Some of them have specific installation needs, so that’s something to keep an eye out for. And then the type of structures that you’re looking for. We also would like to see your design, right? So a preliminary design will be great. If you have a stamp design even better. But we would like to see a design and what you’re looking for.

Project Details for Quotes: The Reasoning

It’s really difficult for us when we get the inquiry for, “Hey, we’ve got this parking lot and don’t have anything designed, but we’re looking for something one to two megawatts.” It’s tough for us to do because there’s no real guidance given there. So when you give us specifics, as far as details of the project, that helps us expedite the quote back to you, knowing exactly what you want and will have fewer questions for you. So the more you could input in here, you also have notes and considerations. The more you could input, as I say, the better it is, the more we’ll know about the project and the quicker the turnaround time will be.

We’re going to start to show you guys some of the different configurations, more standard, typical configurations out there. And then we’ll go into some of the details, some specifics of each of the options.

Solar Carport Configurations

L-Shaped Configuration

The first one we want to show here is the L-shape configuration. Typically with L-shape, you know, you have a single-row parking space, meaning one car will park underneath the canopy. Typically, on the opposite side of the carport, as you see here in the picture, is a walkway or something like that. it’s a single cantilever like you see, and we have offset those cantilevers slightly as well. That is an option that you could look at, but this is a basic L-configuration. It is your most costly option when you look at it because the foundations and the columns are the same sizes.

So this is your basic configuration with the T-shape. The same type of column that’s coming out of the ground. Essentially on this, you’ll have three modules on the north side of the column, three modules on the south side of the column with your standard 72-cell, four types of module.

T-Shaped Configuration

This is a mono slope design, so meaning you’re probably going to face this in the southerly direction since we’re on the Northern hemisphere. And probably the most common that we see is this T-shape right here.

Y-Shaped Configuration

Another interesting design that we have is a Y-shaped configuration. We see this as also a very common configuration, very similar to the T-shape. Essentially here, this is a parking lot that has an east and west orientation. What we do is we have the panels face one another. Again, this is the same, three on one side, three on the other type of configuration. Very common again, east-west with a single post, single column.

Pi-Shaped Configuration

These are quite interesting for a lot of parking lots that may need more panels in a particular space or that have sort of a walkway or an island in between the parking spaces facing one another. Right? So this is very common. It allows us to essentially place four panels on either side. In these pictures here, you have it as the Y-shape. We could also do it as a T- shape. But yes, they’re fully attached to one another and allow for a bit more capacity as far as the structures go. So another great methodology of using with some particular parking spaces that you may have.

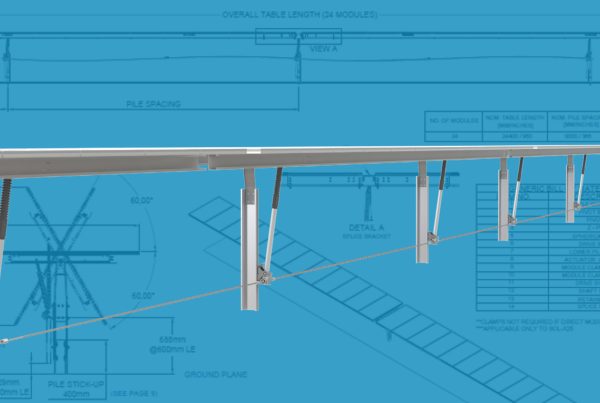

Long-Span Carports

And then finally long spans. We see a lot of long spans in some of these larger municipal parking areas. We also see them on elevated parking decks, where you have a few floors, and then the top floors just open to open air. We’ve installed these long-span arrays there.

If you look at this bottom right-hand corner picture, it gives you a little description of what a long span may look like. You could see the north-south span between columns is almost 100 feet, 97 feet there, and then east-west from post-to-post or column-to-column, essentially that’s typically about 18 to 20 feet, I would say in Northern locations throughout the U.S. and Canada.

Some key product components that we’d like to go over and discuss with you today. As I mentioned before, these systems are very custom.

Foundation Design for Solar Carports

So foundation design, it could be specific, based on the regions. What’s your snow load, wind load, geotechnical conditions, right? What’s in the ground there? Very important for us to design with that. Once we come further down the line in the project, we look at that and, it is one of the key considerations in engineering.

The primary structure is always attached with an anchor bolt to the foundation. No on-site welding is required. Everything is pre-punched in the factory. So again, we’re using those specific module conditions. Modules will have the melting hole position. Very important that, whatever module you choose, you stay with because we are going to set that through our machinery and pre-punch those holes. So very easy for the installation; everything lines up and is seamless on-site.

Secondary structure, custom purlins for your model, that’s exactly what I’m talking about. Everything is corrosion-resistant, galvanized steel. We do have options for higher galvanization if needed. If you’re closer to the shore or maybe a public project that you’re working on and they have higher needs, we could take a look at that, discuss it, and then, pull forward a higher methodology of galvanization. Everything is integrated bonding, we use bonding washers, and of course, we use wire management that’s inherent to our design.

So your modules are then bonded to the structure itself. And then, of course, these structures are anchored deep within the ground. So you have a fully bonded solution.

Design Considerations of Solar Carports

Here are some design considerations to take a look at.

Tilt Angles from Zero to Seven-Degrees

Multiple tilt angles are available. Basically, we recommend from zero degrees to a seven-degree tilt. That’s sort of the range that you want to keep in, and anything greater than a seven-degree tilt, you’re going to look at a higher need for steel.

So heavier steel on-site could be able to hold the wind, snow load, seismic loads, whatever it may be.

Site Topography: From Trees to Stripes

You want to keep in mind any locations of trees, where’s the sun coming from, foundation spacing within the parking lots. We all know typically a parking lot with stripes is nine feet wide. However, you know, when these guys stripe these parking lots, they always come out differently. Having a survey of the site not only for topography but also for the parking stripes is important because we always want to land in between parking spots, if possible. That is our goal. Sometimes we require that given the lay of the land that you restripe the lot. But we do try and avoid that as much as possible. Something that comes out again in the engineering process

Structure Heights

Structure heights, this is a really important one. Is the lot in a fire lane? If you have a commercial, industrial type of parking lot or building that you’re installing these canopies next to? Are there trucks passing underneath, right? So we need to know these heights. Fire lanes include fire trucks, ambulances, emergency vehicles.

We do see issues with waste removal, garbage trucks. Do they need to pass underneath? Very important to understand the host site and what’s happening. Who’s pulling through those parking lots?

Options and Customization of Solar Carports

Next, we’re going to go into some other uses for these structures. We spoke a little bit about galvanization, right? We could give some higher levels of galvanization again if needed.

Powder Paint Coating with Your Colors

Powder coating, as you saw in one of the first slides. We do offer powder coating. You can do many different colors. We have a color palette that’s available. Black, red, green, blue, purple, whatever you could think of. We do see that a lot of, companies do like that idea. Yes, it does come at a higher cost. Of course, the powder-coat feel, with the different colors out there.

Water Management and Waterproofing

Another one that we see often is watertight structures and water management. There are a few methodologies in watertight structures?

There are two ways that we look at it. One is we could install a roofing substructure underneath the panels? And that would give you corrugated roofing underneath the array and be able to shed the water to whichever direction it’s pointing. We add a gutter and leader system as well.

Another methodology of making things watertight is adding gaskets? So no roofing substructure underneath. But we would add gaskets in between the panels, both north and south, east and west. That way, you do get probably 90 to 95% watertight solution. It’s not 100% but it does keep a lot of the elements out, again, 90-95%, from falling through the cracks in between panels.

Water management, so gutters, the leaders, again, is another big topic of conversation in a lot of these projects. We do see this quite often. It’s important to know, when you think about gutters and leaders, where you want the water to go. Where are the drains? And then how much water can the stream handle? Because again, we are redirecting water that’s collecting on top of an array or a roof for that matter if you think about it.

And then pouring all that water into a few centralized locations, so it’s important to understand where does this water go and what drainage systems are in place, what’s the topography of the parking lot? Where’s the parking lot pitched? So that will tell us, “Hey, we want to put a leader in one section of the car parking lot, but not in, maybe another, where it’s uphill kind of thing, and then have the water travel the full way.”

Snow Guards

So those are some things that we want to think about and plan ahead of time. Snow guards, Northern conditions, right? And we want snow guards; we don’t want snow crashing or falling on top of people or vehicles. So we do offer snow guard options. There are quite a few different types of snow guard options that we could offer. And of course, we will look at that on a project-level basis.

Again, everything is highly customizable, so we want to look at the project, figure out the needs and then, you know, apply the most cost-effective and effective solution for the system itself.

Electric Vehicle Charging

Big one coming about right now, EV, of course. Oftentimes, we do get EV charging questions. You can customize the systems either the columns or the whole for EV chargers. We’ve also attached our inverter technologies to the columns. We have some bracket and mounting options there, so you can do things on-site and customize the site to hold other technologies on those columns and infrastructure that we’re giving you.

Geotechnical Engineering Services

One of the services that we offer is geotechnical services. We have a sister company, PRI Engineering, a great company offering geo services, so we can help you explore the level of geotechnical that you need.

Installations Services and Training

We offer installation training for those that do have the installation capabilities but may want a project manager on-site from Polar Racking to help guide through some of the installation efficiencies that we have developed. So we could provide that as well.

Of course, we do offer foundations, installation, and mechanical installation of these canopies. So you could tell us, “Hey, look, we want you to come out and install the foundations.” We would drill out a foundation hole, put steel rebar cages inside the hole, pour the concrete, attach our J- hook assemblies to the concrete, and then drill the foundation columns in place.

And then, of course, assemble the rest of the racking system as well. So these are all services that we offer. You could choose to use them, or you could choose not to. It’s per your discretion, your capabilities of what you’re looking for.

We do also offer module installation. Module installation is just installing the module on top of the racking and bolting it to the racking system. We will not make any electrical connections. Many of the jurisdictions, different states require that you have an electrician on-site to do those electrical connections. So we try and avoid that. We stick to the module mounting and then let your crews take over from there for any electrical connections, or wiring, and so forth.

Frequently Asked Questions

What are the snow and wind load limits?

Typically, we’ve seen as high as 60 PSF snow loads. We have systems out there with 60 PSF snow load. Our other systems out there, in the Caribbean and Florida, have 185 mile per hour wind loads.

One other thing I would like to add is, Polar Racking is a Canadian company. We do see some very harsh environment climates in Northern Canada, that sort of thing. This system was designed with that in mind. This is a very strong, heavy steel structure with installation efficiency kept in mind as well.

How do you determine the foundation requirements?

And we already went over this a little bit, but we do design our foundations based on the local geotechnical information required. So we do need geotechnical information. This will allow us to then engineer the proper structure with different types of foundations that we could do.

Quite typically, most common, I should say, we do see the case on foundations. We’ve also done quite a few systems with spread footers where for whatever reason, the soil conditions will not allow us to go as deep as we need, so we kind of go wide. And then, we also have helical solutions, where we drill a helical pile into the ground, and that is our foundation anchor to the soil.

What are your options for water management?

So again, we offer several options, including a full waterproofing using a roof deck. We also offer gutters and leaders, or we could go with the rubber gasket type of methodology, which will go in between the panels, both north and south, east and west, east and west. And allow full control of the water. You could then direct the water to the gutter system to where we need it in the parking lot to have proper drainage and so forth.

Question Period

This is the part where we open it up to questions. You have my contact information on the bottom left-hand side of the screen. I am Jonathan Mizrachi again, the Sales Director in the U.S. We also have my counterpart AJ. He is managing the Canadian and Caribbean markets if you’re in Canada or Caribbean islands. I’d rather be in the Caribbean islands, a little bit nicer. You know, your choice, but his contact information is there.

When does the 10 to 12-week timeline begin? Does it begin with Start My Order?

No, it begins once we get a purchase order in place and we know what design we’re going with. So yeah, I start my order typically– We start with the very preliminary design and we get some pricing in front of you, so you can tell us where you’re at, so we’ll get you a layout. We’ll get you a price. But yeah, the lead time starts once we get a purchase order and a deposit in place, typically.

Do you have a standard CCDC NMS spec available?

No, don’t believe we have a standard CCDC NMS spec available to be perfectly honest with you. We’ve been asked for this once.

Jonathan: Send us an email and then, yeah, I was just going to say, if you need anything or any requests, you know, you have both my email and AJ’s here on the screen.

You can also use the generic sales of the Polar Racking, and send us an email with what you’re looking for and we’d be happy to help you with that.

Vishal: Yes, thanks for the question, I’m looking forward to receiving the email to dig into that a little bit more.

Have you worked with any customers in Mexico?

Polar has done work in Mexico before, not on carports yet, but we’re very happy to do so, please send us your inquiry, and we’ll get back to you quickly.

Does PRI Engineering do geotechnical investigations in the USA?

Absolutely, PRI does geotech all over the Northeast USA, from New York to Maine, Pennsylvania, and New Jersey. I’ve also done work in the Caribbean and then all over Canada. So definitely, send us your inquiry, and we’d be happy to work with you on that.

With the Y-design, why isn’t it tiled the opposite way in that the high point is in the middle that gives more energy over the day in North-South to provide vehicles with better shading?

We can absolutely do that as well. Typically we find with the Y, people are trying to channel the water, or the snow, or whatever it might be. But we can work at it working in both directions. So if you have a project like that, please send it across.

What is the highest ground clearance you can design to?

Typically on most carports, it’s 10 to 12 feet. We can go higher. We’ve seen 14 in cases where it’s a fire lane. It just comes down to like the higher you go, the bigger the beams that we use, and it directly translates to the cost.

Jonathan: You got to have it in your budget. That’s the end result there. Have it in your budget if you have something in mind. Right now, we’re working on a truck carport, where oil trucks are coming underneath there. So we need a little bit more clearance. You just got to make sure that you have it in your budget, and keep in mind that you will need more steel involved, maybe, in the columns as well as above head and the purlins and so forth.

Are bi-facial panels recommended in any stats?

Vishal: So we don’t have any stats. Bi-facials will work in a lot of cases because when it’s a direct bolt type design, the majority of the panel anyway is exposed at the bottom.

And again typically in your parking lots, you don’t necessarily have a white surface at the bottom. That might not be the right question for us to answer. You might have to figure that out.

That being said, for many of the carports we’ve supplied, we’ve noticed that our customers are using bi-facial modules.

Jonathan: Yeah, just to add there, it seems like a lot of manufacturers now are offering bi-facials over the standard module, especially in the US. I think it’s tariff-related, obviously on the panel side. But yes, I believe that most of the tiles that we’re seeing on newer projects are bi-facial. I do believe that is because of price and tariff-related from the panel manufacturer side.

I’m sure you could run some modeling. Bi-facials are recommended from a production standpoint with some of these design software out there. It’s not something that we would do at Polar. But if you give us the module and specifications, we can certainly design a system to meet your expectations.

Vishal: Yeah, exactly. So thank you for the question. Again, you have all our contact information on the screen. We’re very much looking forward to hearing from you with your additional questions or additional project information. As Jonathan said, we take great pride in the fact that we have designed a very robust system and one that will look nice for you and your customers. Because the system will, as opposed to a standard rooftop or ground mount, be seen every day.

So it’s very robust, it’s a good-looking product. We feel like we can offer you the support that you need to get your project off the ground from below ground, all the way up. And yes, we’re happy just to work with you. Any other thoughts there, Jonathan?

Jonathan: Yeah, just like I said, our contact information is there on the screen. If you have anything that you want to ask offline, please feel free to give either AJ or me a call. Happy to answer any questions that you may have, review any designs that you may have – whatever may come up. That’s what we’re here for.

We’re willing and able to help you with your project needs. I think that’s something that sets us apart from some of our competition is the personal service that we give. So just want to put that out there again. Feel free to reach out and anything we can do to assist and help you with your project, just let us know.

Vishal: Perfect. All right. Well, yeah, thank you again for your time. We really do appreciate it. And yeah, we look forward to hearing from all of you.

Have a great day.

Jonathan: Thank you, everyone.

Get In Touch

At Polar we take pride in providing courteous, efficient and quality service to our clients. Contact our support for any customer inquiries.

Recent Posts / View All Posts